Most machines are threaded in a similar way, following four or five steps. Make sure the needle and presser foot are raised.

Follow the diagram on the top of your machine to begin threading the top thread. Take it round the notch as shown.

Take the thread down and round the rectangle marked with an arrow in the direction shown. This takes it through the tension discs.

Take the thread up to the metal hook, which should be raised and visible. If it is not, turn the balance wheel on the right to raise it. Pull the thread round the hook from right to left and down to the needle.

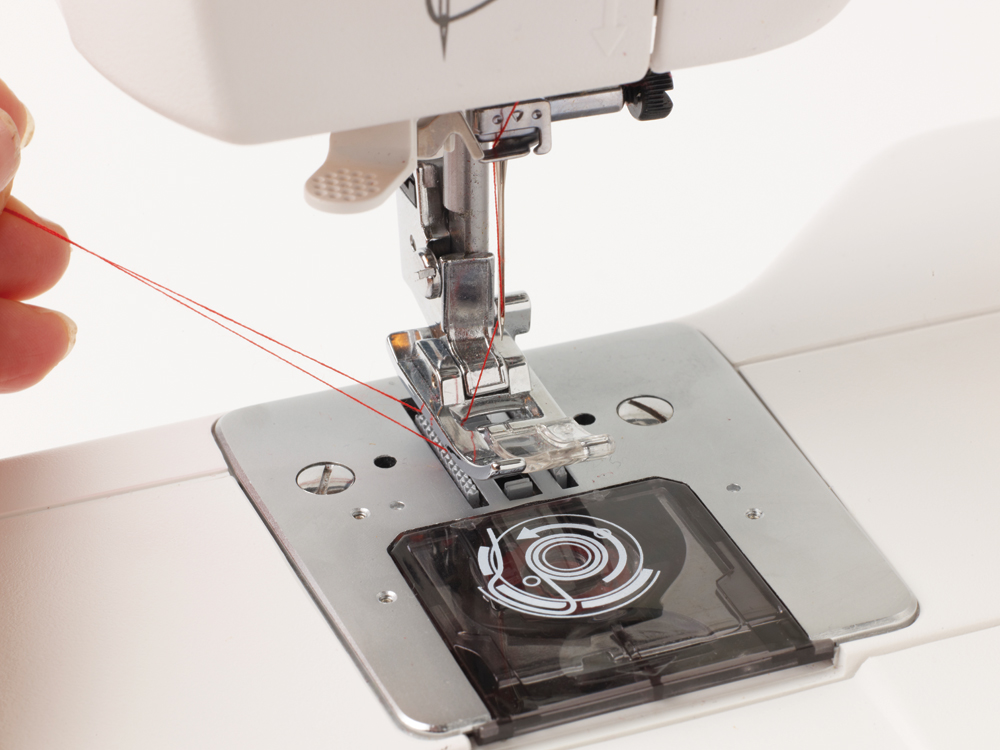

Feed the thread behind the hook above the needle. Lower the presser foot.

If you have a needle threader, pull it down fully with your left index finger and hold it down. The threader arm will wrap round the needle.

Holding the thread in your right hand, hook it under the left fork of the threader, then under the smaller right fork.

Release the threader. There should be a loop of thread coming out of the back of the needle. Pull on the loop.

To pick up the bobbin thread, turn the balance wheel by hand towards you. This takes the needle down and up again and brings up the bobbin thread. Pull the loop free to pull out the thread end.

Hold both threads to the back and put on the lid to the bobbin compartment.